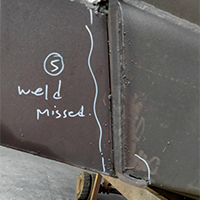

Time of flight diffraction (TOFD) is one of the most reliable non-destructive testing methods in testing welds for both pre-service and in-service inspection. An accurate assessment of welds is vital to ensure that the stability and integrity of welded structures is not compromised by defects.

A pulse echo is an A-scan presentation broadly used for thickness measurement and sizing the defect in an ultrasonic inspection involving identifying the indication echoes when the signal is reflected from a discontinuity in a test material structure in weld joints pipe and plate.

Eddy-current testing is one of many electromagnetic testing methods used in nondestructive testing making use of electromagnetic induction to detect and characterize surface and sub-surface flaws in conductive materials.

Radiographic Testing (RT) is an NDE technique that involves the use of either x-rays or gamma rays to inspect non-uniform materials. industrial Radiographic Testing (RT) makes use of X-ray or gamma radiation to create images that can show defects hidden inside the material.

In addition to producing high quality radiographs, the radiographer must also be skilled in radiographic interpretation. ... All of these steps make use of the radiographer's visual acuity. Visual acuity is the ability to resolve a spatial pattern in an image.

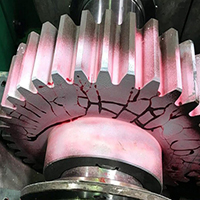

Magnetic Particle Testing (MPT), also referred to as Magnetic Particle Inspection, is a nondestructive examination (NDE) technique used to detect surface and slightly subsurface flaws in most ferromagnetic materials such as iron, nickel, and cobalt, and some of their alloys.

The principle of liquid penetrant testing is that the liquid penetrant is drawn into the surface-breaking crack by capillary action and excess surface penetrant is then removed; a developer (typically a dry powder) is then applied to the surface, to draw out the penetrant in the crack and produce a surface indication.

Destructive testing ( DT ) is an essential process in the materials selection and approval process for high-performing materials. DT is often performed on low-cost, high-volume components.

HEAD OFFICE

#1B Macarthur Park , Macarthur Ave , Robindale , Randburg, 2194 , Johannesburg South Africa.

CELL : +27 66 333 6233, Email : info.sa@metaltechinspec.com

© Copyright 2021. All Rights Reserved.